What is a round sling?

As mentioned, you can complete the most diverse lifting jobs with the round sling. Although lifting slings and round slings fall under the same category, there are differences. The polyester round sling differs from the lifting sling in that it is endless and does not have two ends with a loop. This makes it easy to lift directly, in a sling position, in a parallel position or at various angles up to 60°. If you are going to lift a load that must not be damaged, a polyester round sling is ideal compared to metal lifting equipment. Compared to, for example, lifting chains or tension chains, the polyester round sling is low in weight, easy to store, inexpensive to purchase and not susceptible to rust. The round sling is also easy to maintain and inspect. At Hijsjob you can buy the appropriate high-quality round sling online at a competitive price. All round slings meet the European standards (NEN-EN 1492-1 / NEN-EN 1492-2) and safety requirements. Round slings are available with an EKH certificate with which you can demonstrate that the round sling is certified.

Colored round Slings

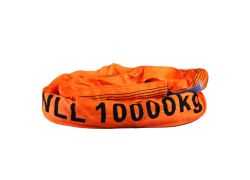

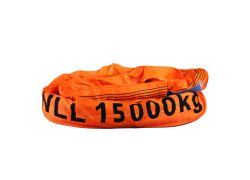

The round slings have their own color codes that show the maximum workload of the lifting equipment. These color codes are universal, but the maximum working load should always be stated on the label of the round sling. With the color codes you can easily distinguish round slings from each other.

How do you use a round sling?

The round sling can be used for various jobs and in many different ways. Basically, a round sling is mainly used for lifting and securing a load.

Lifting

A common way of using the round sling is slinging. The round sling goes around the load or the attachment point, after which the end is put through the eye of the sling. This end is attached to the hook and so it can be lifted. With slings, the maximum workload decreases by 20%. When you lift directly, in a parallel position or at an angle, this also affects the maximum workload of the round sling. Always check the label present for the guidelines.

Securing cargo

When you are going to secure a load, we advise you to always use a lashing strap. If there are no attachment points for the lashing straps, a round sling can be the solution. Load securing with a round sling is possible in many different ways. When the round sling is used as a head lashing or as a lashing point, the maximum load, i.e. the Load Capacity (LC), of the round sling may be just as great as the specified maximum working load (WLL). The LC is a way of indicating the force required to hold the load properly in place. With an LC of 3500 daN you need a round sling with a WLL of three tons. In order not to overload the round sling, the WLL must always be higher than the LC. This way you ensure that the round sling can also be used for lifting purposes.

Lifespan Round sling

The hooks influence the life of the round sling during both load securing and lifting. If the hook is too small, this has negative consequences for the breaking strength. Constriction causes the fibers to pinch. It is important to protect the cargo with sharp edges. Sharp edges can damage the round sling.

How do you maintain a round sling?

Proper storage is essential to ensure that you can use your round sling for as long as possible. Never store a round sling outside. Weather conditions and temperatures can affect the round sling. Never leave the round sling on the ground or in an environment where a lot of dirt such as grease or debris can affect it. By using a storage box, you can safely store round slings out of reach of UV light.

What do you check before use?

In addition to the periodic inspection by an expert certified inspector, the round slings must always be checked before use. Because although timely inspection contributes to safety, it does not guarantee no intermediate defects. Always check the round sling before use at least on the following points:

Designation

A round sling must always be provided with a clear indication of the maximum working load. This is stated on the label, as well as the manufacturer, material type and load factor. Is the label missing or is the information illegible? Then immediately put the round sling out of use.

Damages

When a round sling is damaged, this can have major negative consequences on the breaking strength. So always check whether the round sling is still in good condition. Are there no cuts and are the stitching still intact? Has the round stopper not been affected by, for example, heat or chemical liquids? Immediately remove the round sling from use if any of these points are in doubt.

Advice

Do you have questions about which round sling is suitable for your lifting job? Please contact one of our advisors.