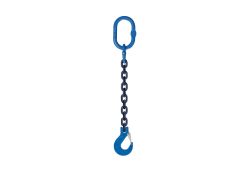

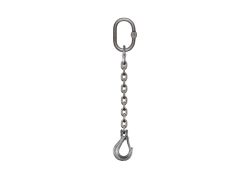

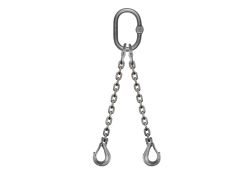

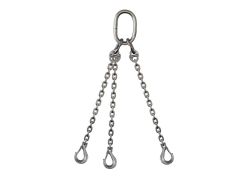

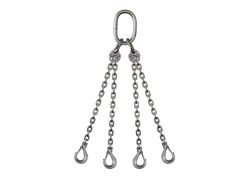

Step 1: Determine the number of chain sling legs.

To be able to lift a load, it must be equipped with lifting points. Match the number of legs of the chain to the number of attachment points of the load. For example, choose from a chain sling with one, two, three, or four legs.

Step 2: Match the workloadlimit of your chain to the load.

Chains are available in various diameters. The diameter of the chain and the material together determine how much the chain can lift. The number of chain legs and the angles they make in relation to the load also influence the maximum working load of the lifting chain. In the diagram, you can read which safe workload you need from different angles.

Step 3: Determine whether the lifting chain needs to be shortened.

When attachment points are not at the same height, the legs can easily be shortened with grab hooks. Grab hooks can be mounted separately on the masterlink, or you choose a top link with shortening hooks. The latter variant is more durable because there are fewer moving parts. Shortening hooks are also often attached for the purpose of maintaining flexibility. Because you can easily adjust the chain to size, you can use it for different purposes.

Step 4: Determine the length of the lifting chain.

This is referred to as working length or chain length. The working length is the length from the inside of the top link to the inside of the hook (the effective length of the chain).

Step 5: Choose the material that fits the working environment.

When you choose Liftinggear shop, you choose quality. We, therefore, work exclusively with products made of strong steel. Grade 100 is a high-strength steel that allows lifting chains to handle a high workload. Within an environment where corrosion can play a role, stainless steel offers a good solution. Stainless steel chains have a more limited range when it comes to maximum workload compared to Grade 100.

Step 6: Choose the hook.

There are many possibilities and exceptions, but the most common variants are the self-locking hook and the latch hook. With a latch hook, the latch opens inwards, which is ideal for quickly picking up the load. With a self-locking hook, the hook opens outwards by means of a catch at the back. The advantage of a self-closing hook is that the latch is part of the hook itself, which ensures strength and safety. Due to the weight of the load, the hook closes immediately, which means that the hook cannot open unintentionally during lifting.